Fridays (in 2023) means that it’s time for another CPO Rising Listicle. Each list will include a variety of procurement tips, trends, insights, research, lists, strategies, and/or recommendations designed to help procurement teams improve operations. We’ll also include a summary graphic for you to share with your team.

Gaining visibility into and control over supplier risk can be challenging even for sophisticated enterprises with dedicated risk management teams. The task requires constant monitoring of multiple sources of information, different perspectives on risk, and a willingness to reach across the enterprise for help in managing risk and achieving and maintaining compliance. As a result, here are six recommendations.

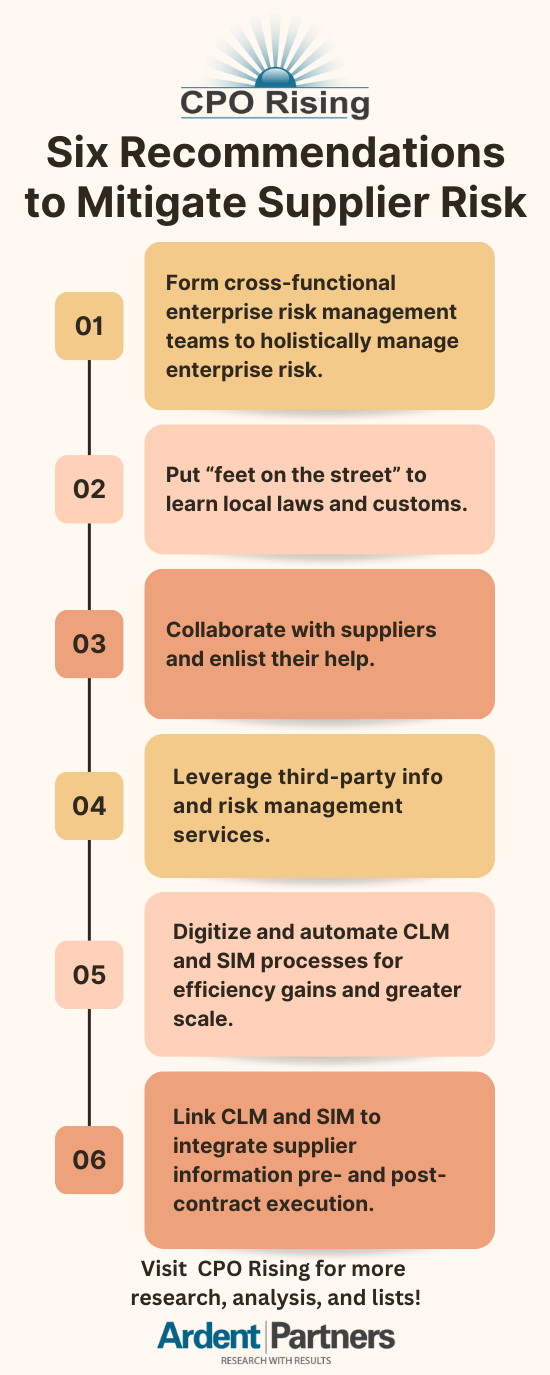

Six Recommendations to Mitigate Supplier Risk

- Form cross-functional enterprise risk management teams to holistically manage enterprise risk. Since risk and compliance take multiple forms, it is prudent for CPOs and procurement leaders to enlist help from across the organization in order to round out their ERM teams. Representatives from legal, IT, and the business can work with procurement to collaboratively sketch the supply and supplier risk management landscape with greater detail and be better prepared.

- Put “feet on the street” to learn local laws and customs. Part of the challenge of operating overseas is that experienced business leaders and practitioners often lack knowledge of local laws and cultures, which can imperil business processes and expose organizations to myriad risks. Sending advance teams, or enlisting local representatives who can help orientate the organization in the culture and business customs is key.

- Collaborate with suppliers and enlist their help. Suppliers know their markets as well as, if not better than, their customers. Suppliers are also (or should be) familiar with laws and regulations, and can be valuable business partners when it comes to managing supply risk and achieving/maintaining internal and external compliance.

- Leverage third-party info and risk management services to round out risk management teams.When internal and supplier data fall short of painting a complete picture of a supplier or category’s risk, there are third-party information services available that can provide organizations with the financial, legal, operational, and security information to add granularity to the picture. Other third-party service providers can provide tailored risk assessments and risk management programs for enterprises that cannot stand up or scale up their own programs in time.

- Digitize and automate CLM and SIM processes for efficiency gains and greater scale. Modern contract and supplier management solutions can perform much of the heavy lifting involved in managing contract and supplier information, allowing practitioners to shift their focus to building collaborative internal and external relationships, analyzing risk, and strategically planning for the future. CLM and SIM adoption correlates with enhanced enterprise performance in the form of greater spend under management, identified and realized savings, and greater internal compliance.

- Link CLM and SIM to integrate supplier information pre- and post-contract execution. The value of these solutions can be extended even further by linking them to leverage the full supplier information lifecycle. Cloud-based, user-friendly solutions and suites can enable users to aggregate and manage supply, supplier, and third-party risk from across the enterprise in one location, which can streamline the process, improve user experience, and round out risk profiles for more accurate assessments.

RELATED RESEARCH

Managing Supplier Risk in a Tough Global Climate

Supplier Performance and Risk Management – Bosom Buddies

The Future of Supply Risk Management

The CPO’s Approach to Supply Risk

The Key Themes for the Modern CPO’s Agenda (#11 – Supply Chain Risk Management)

MORE GREAT CPO RISING LISTICLES

Tagged in: Contract Lifecycle Management, CPO Rising Listicle, Lists, Strategy, Suppliers, Supply Risk, Technology