[Editor’s Note: Over the next few weeks on CPO Rising we are publishing some “best of” 2020 articles as we reflect on the year and prepare for the new year ahead.]

Ardent Partners, the established leader in supply management market research, has identified unprecedented levels of risk across the vastly complex and highly interconnected supply chains that drive and support the global economy. Compounding the risk is the fact that these supply chains are universally untested, leaving a majority companies ill-prepared to deal with any near-term global shock or risk event.

Today’s global supply chains are a largely 21st-Century phenomena, driven by the demand for lower-cost sources of supply and production and bolstered by the rapid advances in technology and communication. These global supply chains delivered extraordinary value to the Western-based corporations that initially moved supply off-shore in the pursuit of lower costs. Over the ensuing two decades, manufacturing capabilities expanded rapidly across the traditional low-cost regions (including Asia, Eastern Europe, as well as regions within Africa and across Central and South America) spawning the current age of globalization and innovation.

In the face of heightened geopolitical and economic uncertainty and an increase in “event-specific” risks, like the current coronavirus outbreak, political upheaval within specific countries, new and erratic trade policies/agreements, and environmental events, it has gone largely unnoticed that global supply chains, by and large, are ill-prepared for any major global shock or event and remain almost universally untested.

In fact, Ardent Partners’ latest supply management research covering more than 700 global enterprises has shown that

- 79% of all businesses lack a comprehensive risk management program in place for their strategic suppliers.

- 66% of all businesses lack an active supply risk management program.

- Only 9% of all businesses have prioritized improving supply risk management over the next 12 months.

What Are CPOs Doing to Manage Supply Risk?

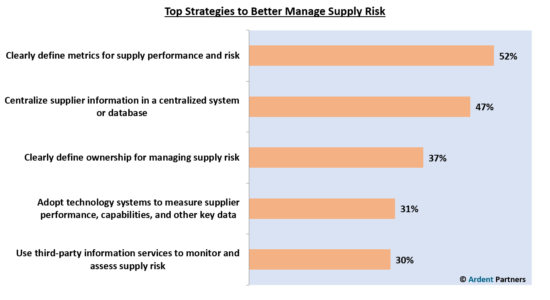

As an enterprise’s supply base morphs and evolves, so too must the approaches taken to manage the risk found within it. As disruptions take new and, sometimes, unsettling forms, Chief Procurement Officers must ensure that they leverage a broad array of capabilities and strategies to effectively mitigate supply risk. The Figure below below presents the CPO’s top strategies to better manage supply risk.

Developing clearly-defined metrics for supplier performance and risk is the most popular (52%) and, perhaps, the most critical avenue for managing supply risk today. What gets measured gets done, but what gets measured also gets attention. Having metrics designed to track supplier performance and risk helps frame a supplier dialogue focused on the things that matter most.

Capturing supplier information management in a centralized system can enable enterprise-level visibility into the key data and information that defines a supplier relationship. In a time where collaboration is critical to success, the ability for internal stakeholders to easily access supplier information can make a big difference between acting proactively to minimize risks and acting reactively to a new emergency.

Supply risk management programs benefit by having multiple stakeholders who can utilize a variety of skills (and enterprise access) to help improve supplier performance, but they also benefit by having one owner or “throat to choke” if something goes awry. Increasingly that throat belongs to the Chief Procurement Officer or someone within procurement who is trained and equipped to “speak” the language of suppliers and accurately communicate various risk levels based on existing information and insights.

Summary

The moving target of supply risk management is only getting harder to hit in today’s global, hyper-kinetic business world. The bigger an enterprise’s global footprint is in terms of customers, locations, infrastructure, suppliers, and supply chain, the greater the chance that something, somewhere, could go wrong. Moreover, identifying, prioritizing, and mitigating (or accepting) risk without the right people, processes, and technologies in place to collect and analyze supply risk information in a timely manner is all but impossible.

Best-in-Class CPOs have remained more proactive and vigilant in their supply risk management efforts and have reaped rewards from these efforts. Other CPOs and procurement leaders would be wise to follow their example and invest time and resources now to ensure that their organizations are ready and better able to respond to the uncertainty that looms large today.

RELATED RESEARCH