[A note from the editor: In August, Andrew posed the question – How Do You Define Spend Under Management? – to our audience and invited them to share their views because we think that it’s time for the procurement community to find and adopt a broadly accepted definition of the metric. Today, we feature another “answer” in what we hope will be an ongoing discussion on these pages and across the industry. If you are interested in sharing your views on spend under management, email us or post a comment in our LinkedIn group, we’d love to hear from you.]

Using Spend Under Management Principles to Drive Improved Financial Performance

By Steven Griffiths and Jack Hess of Xeeva

Summary

Ever wonder why many companies view indirect procurement as a non-strategic function? Maybe it’s that indirect practitioners often focus too narrowly on measuring just the cost savings from sourcing initiatives. Maybe they lose sight of how those initiatives connect to core financial metrics, e.g., total cost of ownership (TCO), operating profit, working capital and cash flow. Therefore, adopting a well-structured spend management framework that establishes that connection can bring real value to the business.

The concept of Spend Under Management (SUM) supported by next generation, intelligent procurement and financial technology provides exactly that framework. Implementing SUM helps companies to advance themselves along a five stage maturity model where best-in-class sourcing and procurement organizations not only drive alignment with key financials but also deliver cost improvements that at a minimum are two to three times higher than average organizations.

Key Challenges

- Limited visibility and influence of procurement on indirect spend: Most procurement organizations suffer from a lack of visibility and management of 60-75% of indirect spend. Some of what’s being missed is misclassified in financial systems, some is represented by maverick spend outside of the systems, some is bundled in managed contracts, e.g., real estate management, and some is maverick spend by functional departments without involving purchasing.

- Procurement organization objectives not crisply linked to business metrics: Most organizations don’t have the secret decoder ring that connects indirect spend cost savings to core financial metrics. It’s as much an issue of traceability of savings as it is understanding cost savings impact. Additionally, myriad operational metrics are impacted by indirect procurement and those dynamics are commonly not tracked or well understood.

- Impacts don’t translate to the bottom line: The pressure to deliver real, measurable results from the procurement team’s hard work is increasing and typical approaches to link sourcing activities to budgets just don’t cut it. Most organizations lack a closed loop process that connects source to pay (S2P) projects to a financial commitment from the budget holders.

- Organizational resources wasted on non-value added activities: Whether it’s intervention due to supplier quality or performance issues, invoice reconciliation, or accounts payable follow-up, a disproportionate amount of the organization’s time is spent chasing non-value added transactions.

The Solution: Adopting a Spend Under Management Framework:

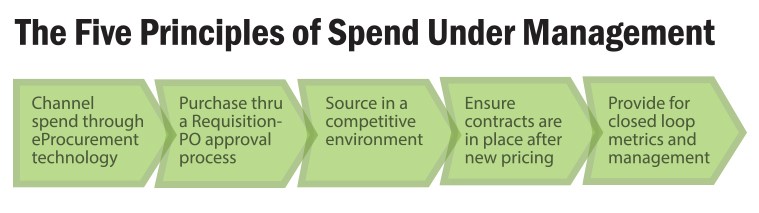

So how do you put in place the right set of actions to ensure that the indirect procurement organization is an effective contributor to the business and can address these challenges? The answer lies in adopting and managing to a SUM framework built on five key operating principles (below) across sourcing, contracting, buying, and spend decision-making.

Push spend through technology. Basic procurement technologies bring some benefit through automation, but real value comes from intelligent procurement technologies that capture data and knowledge, and then transform them into action and positive outcomes. How many of the organization’s resources are tied up performing routine or non-value added tasks? How much time is spent cutting raw data into inflexible Excel charts? Is there a way for the organization to see a shared view of data? Are your suppliers still transacting manually?

Push spend through technology. Basic procurement technologies bring some benefit through automation, but real value comes from intelligent procurement technologies that capture data and knowledge, and then transform them into action and positive outcomes. How many of the organization’s resources are tied up performing routine or non-value added tasks? How much time is spent cutting raw data into inflexible Excel charts? Is there a way for the organization to see a shared view of data? Are your suppliers still transacting manually?

Purchase through a formalized requisition to purchase order process. The organization should be governed by policies and procedures that are complete and universally enforced. Are all the spend areas incorporated? Does the procurement system reinforce these through workflows and business rules? Is that system intelligent enough to accommodate the differences in requirements by category or region?

Source in a competitive environment. Easy enough to understand but for myriad reasons not always applied. How you maximize the business value of sourcing varies significantly based on category, region and end-customer needs. Are there well-articulated category strategies and playbooks customized to business needs? Are savings strategies developed for each functional leader? Are functional managers committed to running all of their spend through the process?

Ensure contracts are in place wherever possible. Well-structured contracts are essential to gaining efficiencies, reducing risk, and managing effective partnerships with suppliers. In most categories, 70-90% of spend should flow through contracts or catalogs. Does the procurement team have the skills and market knowledge to rapidly bring market insights to the functional organization? Has the organization captured best practices in its contracts? Is there leakage or maverick spend bypassing defined processes?

Provide for closed loop metrics and management. A performance measurement and management system is a key success factor in achieving maximum sourcing strategy acceptance and savings capture. Are indirect spend objectives aligned with core financial metrics by business unit (BUs) or function? Are enterprise objectives determined through robust spend? Are cost savings targets are explicitly linked to operational objectives? Can teams see an accurate picture of progress?

Benefits

The SUM framework provides executives with a simple outcome-based model to drive benefits such as:

Alignment of spend objectives with financial metrics

- Actual spend defined at a granular level

- Enterprise objectives defined by business unit and P&L

- Cost savings tied directly to financial objectives

- Details on how cost savings plans will be executed

- Increased visibility and accuracy into forecast savings

Significant improvement in results

- 20-40% less maverick spending and savings leakage

- 5-10% reduction in working capital requirements

- Incremental ROI on existing technology investments

- 2-3 X improvement in sourcing savings

- Overhead as a percentage of sales down 2-3%

Conclusion

Indirect spend represents one of the largest controllable elements of corporate cost. The SUM framework provides a holistic approach to shaping the goals and actions necessary for a business partnership between P&L owners, functional heads, and procurement. SUM transforms what could be a complex and overwhelming effort down to a few basic principles with very clear actions. These principles shape how companies can revamp policies and procedures in the context of best practices, develop and assign savings strategies tied to core financial metrics, establish a management system, and implement supporting intelligent procurement and financial technology.

The Authors

Steve Griffiths, EVP and Chief Strategy Officer. Steve is an industry veteran in procurement, supply chain, and MRO, and is responsible for Xeeva’s business strategy and its execution in product, value added services, and sales and marketing.

Jack Hess, Chief Value Officer. Jack is responsible for ensuring Xeeva technology, team members, and resources are positioned to deliver immediate and sustainable value to our clients. Jack is a seasoned industry veteran, trusted advisor to several Fortune 500 companies, and a pioneer in Spend Under Management.

RELATED ARTICLES

A Proposed New Definition for “Spend under Management”

How Do You Define Spend Under Management?

Spend Analysis: The First Strategic Sourcing Pillar