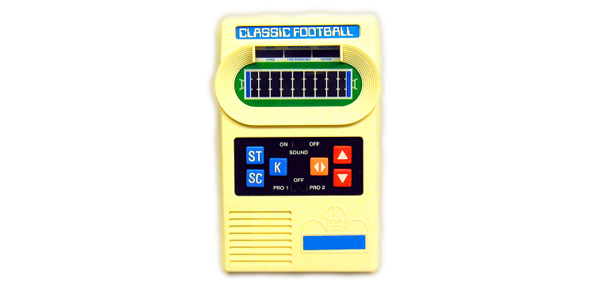

We’ve all heard the annoying little caveat, “batteries not included.” It accompanied just about every toy advertisement of our youth, and perhaps made us (or our parents) a little less likely to purchase that product knowing that it wasn’t turnkey. Thankfully, at some point in recent times, toy companies figured out that including batteries with their toys really wasn’t so hard after all. And get this, millions of their customers are that much happier and have a much better experience because of a very simple change/inclusion. Talk about value-added!

Wednesday Morning Query: What are the things that procurement should start including with its ‘products and services?’

The Context

I once worked for a company that required certain document templates (MS Word files) to be used for different business purposes. It was a very immature organization, still is actually, and several of the most heavily-used templates had fairly significant flaws or mistakes. Instead of fixing the templates and quickly updating them for usage, the organization chose to push the responsibility for making corrections to the individual template users. Instead of solving the problem once, the same problem had to be solved over and over again. Intentional or not, this communicated that quality was not job one and that staff time was not valued.

Are there situations or processes in the supply management operations at your enterprise that indicate, intentionally or not, that quality is not important and that stakeholder time is not valued? How often are these situations or processes repeated? What can you include with relative ease that will add great value to the larger process?

- Do you include a “Deal Memo” (that highlights pricing and key terms and conditions) to the General Counsel’s office when they take over contract negotiations?

- Do you include an FAQ list with screenshots with every supplier invitation to an eSourcing event?

- Do you include a “cheat sheet” for AP to understand all pricing and payment arrangements with new suppliers?

- Do you include a memo to the business users explaining the rationale and benefits of why a new supplier is being implemented?

- Do you include a list of evaluation criteria for staff when rolling out next year’s MBO plan (or do you wait until the end of the evaluation period to pull something together)?

In procurement, how many opportunities are missed each day to include the batteries? Now more than ever, Chief Procurement Officers and procurement teams need to ensure that they are providing greater value throughout the organization – both for their sake and their company’s sake. As one of the most influential players in the Procure-to-Pay process, it’s a missed opportunity if procurement doesn’t provide the proverbial batteries with the goods and services they source and the terms they negotiate. Over time, failing to go the extra mile will erode procurement’s value within the enterprise, and perhaps cause it to lose power or influence within other business spheres.

As we’ve previously stated here on CPO Rising, it is much easier to retain influence than to win it back. So do your team and yourselves a favor and don’t forget to include the batteries.

RELATED ARTICLES

What Buyers Should Know about Supplier Relationship Management: One Supplier’s Take

Why Procurement Effectiveness is the Foundation of Sustainable Success

Skills for the Modern Procurement Pro – The Sourcing Process