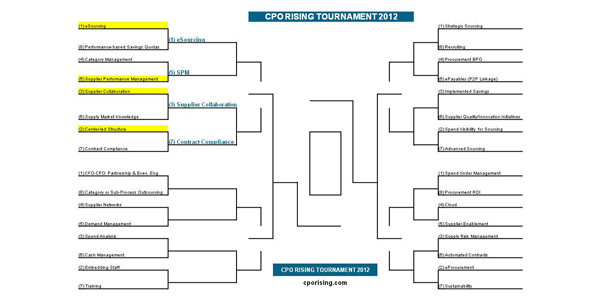

What is the best CPO tool or strategy in 2012?

Our field of 32 determines this year’s champion

Yes folks, it’s March Madness, Chief Procurement Officer Style, where the different procurement tools and strategies compete to get to the CPO’s Final Four.

Day Two (Yes, we’re going daily):

Part of the magic of the CPO Rising Tourney (aka “The Big Dance“) is that if the right tool gets hot at the right time, it can win it all. Day two certainly proved that and featured two very interesting games. The first is a bruising match-up between two similar, yet distinct supplier strategies; while the final game, left the fans of one classic Best-in-Class strategy speechless (and in tears). We take you to the games now.

Region One – (3) Supplier Collaboration vs. (6) Supply Market Knowledge

With many mature procurement organizations starting to focus more of their resources on supplier management, there was a group of hardcore fans with an intense rooting interest in this game; but to the larger marketplace these two teams, despite their seeds, are largely unknown in practice.

Supplier Collaboration came into the game on a huge winning streak – not only did analyst firm, Ardent Partners use it as a major theme in its large 2011 CPO Rising Report, but the word “collaboration” has been such a hot word in the parlance of business strategy. Conversely, Supply Market Knowledge, a tool garnering significant attention among mature sourcing organizations, remains enigmatic – able to deliver huge value, but lacking in definition or structure and without a standardized approach within most companies and within the market as a whole.

At the start, Supplier Collaboration (“SC”) leveraged its over-sized starting team that focuses on Direct Material suppliers to drive cost savings across their “supplier’s supply chains.” Supplier Collaboration, however was quickly hit with a technical foul, because technically, most of this type of “collaboration” is actually not collaboration at all, but rather, a buying organization mandating supplier participation to maintain its current level of business. During a television timeout, the SC coach argued that the high-profile Open Innovation programs driven by the CEOs of many Fortune 500 companies, are based, at their core, in building better supplier relationships and collaborating to mutual gain – and just like that, Supplier Collab. got back into the flow of things at the hub of business relationships.

Supply Market Knowledge (“SMK”), bolstered by the internet where all information is free or at least very affordable [Sidebar: AP Leaders click here for an example of some “very affordable info” :-)], struggled in the first half to get a game-plan going. The availability of information has made it incumbent upon sourcing teams to develop a minimal amount of SMK to ensure that suppliers aren’t in the headlines for any dubious, unethical, or illegal activity. But, the way SMK is performed in most companies is as a form of CYA (“cover your – – -“), not as a progressive game-changing tool that can be used to drive wholesale changes across a supply base. With so many sourcing projects failing to identify new suppliers and simply using the same bid panel from the last sourcing project three years ago, the game quickly went south for SMK as they bowed out at this early stage.

Said the game announcer, “There’s a ton of promise in this young SMK team. We see more and more third-party services providing value in this area and a few solution providers are starting to take real-time SMK and embed it within their Spend/Sourcing dashboards. But, trading partner (sic) collaboration is at the top of its game (from a perception standpoint, not reality necessarily) and will be a tough ‘out’ in future rounds.”

Region One – (2) Center-led Structure vs. (7) Contract Compliance

To close out Region One’s first round (we really should have named the Regions), we have a veritable David v. Goliath encounter between two long-standing CPO value drivers.

Goliath: Center-led Structure, with countless high-profile CPOs who have adopted this structure as a way to transform their organizations

David: Contract Compliance, whose simple mantra of “pay only what was agreed upon from approved suppliers” is both commonsensical and realizable by procurement departments of any size (Center-led just shuddered as they read that last sentence).

Goliath swung first with the force of dozens of Best-in-Class procurement departments who realigned themselves to have a centralized view of the organization without centralizing all procurement decisions and staff. Having the best of both worlds (control, with freedom), Center-led has no visible weaknesses in its game to exploit and they thundered out of the blocks like a lightning-fast CPO tool in track shoes, if such a thing were to exist.

But Contract Compliance (“CC”) was unfazed and in its best Crocodile Dundee voice said, “That’s not a punch…. long pause…… long pause……. That’s a punch!” and proceeded to deliver a figurative flurry of kidney punches and haymakers in the literal form of one borrowed internal auditor, five low-paid temps, a conference room and boxes of paper contracts and a massive excel dump of last year’s invoice detail. And, lots of time. Never before had so much potential value been delivered from such a rag-tag bunch. By attacking non-compliance and finding savings (according to Ardent Partners, every non-compliant dollar costs the business somewhere between an extra 6% and 16%), CC leverages and reinforces previously done work.

Center-led, a tool that led to the usage of so many other tools, was not used to playing from behind and a sense of desperation quickly overcame it. Yes, it was an acknowledged best practice, but centralization is also an effective strategy and that point is often overlooked. The real underlying keys to the Center-led strategy are gaining visibility, establishing policies, and standardizing processes across the enterprise. But, for the value to be realized, a true transformation must occur. And, transformations take real work and result in an intentional disruption of operations.

So, while a move to Center-led is a change we can believe in, not every procurement department is positioned to lead that change successfully. Contract compliance on the other hand is a project that even the least capable among us can advance. It can be greatly improved by automation and visibility, but a good old-fashioned audit performed by low-level resources has the opportunity to find savings.

Do You Believe In Miracles?????????? YES!!!

Contract Compliance advances!!