Riddle 1: When is a door not a door? When it’s ajar.

Riddle 2: When is a penny not a penny? Since 2006.

2006 is the year when the cost to produce and deliver a penny exceeded its face value. Last year it cost the US mint 1.62 cents to produce and ship a penny. Talk about pound foolish. The nickel is in no better shape (Hat tip: Coin Update News :-)). The US Mint is losing a mint (literally: $45 million) on these two coins annually and it seems like they’re trying to make it up in volume.

The US is not alone in its coin production woes. The Canadian penny is under siege from some quarters (heh-heh!) and several countries in the EU have stopped producing the Union’s smallest coins. With the cost of coin production spinning wildly out of control, the White House has recently proposed making changes (see page 100) to the composition of its coins (perhaps following the lead of one brave congressman a few years ago), and believes that “using alternative coinage materials could save $150 million annually after an initial period of development and capital adjustments.” Say, that’s a nice piece of…. wait for it…… change. But the inevitable defenders of the status quo have already weighed in, voicing their opposition. I, for one, would certainly never bet against “Big Coin Laundry” which has been known to share tricks with those other “Big” industry titans – “Big Tobacco” and “Big Oil.” One thing is certain: as our friends over at coinflation.com put it, “It will be very interesting to watch how this unfolds.” Stay tuned.

At some level, I wonder why countries around the world wouldn’t just do what the Japanese have done for years and punch holes in the middle of their coins. This has the double benefit of making them cheaper to produce AND easier to carry (see Easy to Transport and Production Costs sections).

Despite what this group promotes, I also wonder what would happen if we eliminated the penny? And, if we did, what would happen to all those great penny-based ideas and sayings like – penny jar, penny ante, penny loafers (do people still wear these?), penny hardaway, a penny for your thoughts, take a penny-leave a penny, penniless (Note to self, register the url nickeless.com asap).

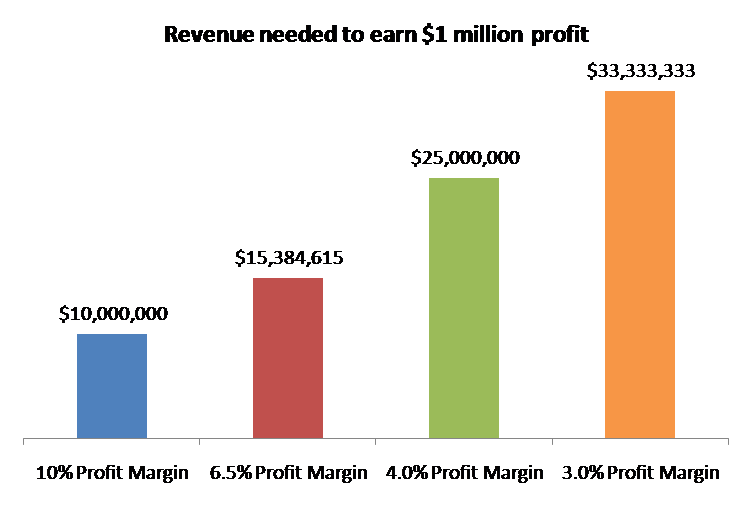

One phrase that has long been out of vogue amongst procurement pros is Ben Franklin’s old maxim, “A penny saved is a penny earned.” If Ben Franklin had worked in the 21st Century, he would have quickly realized that the average profit margin across different industries would mean that the benefit of one penny saved in business is, in fact, much more than one penny earned. Here’s a visual for what I mean.

For example, if you work for a company that has a 4% net profit margin, that company must generate $25 million in revenue to earn $1 million in profit. Now compare the effort required to generate that revenue with the effort required to save $1 million in procurement. Powerful!

When it comes to profitability, procurement has extraordinary leverage. It is why more and more CEOs are focusing on procurement efforts. To paraphrase Method Man, “If you’re not making saving dollars, you’re not making sense.”

In the next article, we will walk through this discussion in greater detail, provide some industry benchmarks, and show how this analysis can be performed with a hypothetical company and procurement department.

Tagged in: Finance, Performance, Strategy